In modern construction, especially in roofing and structural framing, engineered trusses have become the standard for their strength, efficiency, and cost-effectiveness. However, behind every prefabricated truss system lies a critical layer of accountability and verification: truss certificates and documentation. These records are not mere formalities—they play a vital role in ensuring that the structural components meet safety standards, comply with building codes, and match the unique requirements of each construction project. In this article, we’ll explore the importance of truss certificates and documentation, how they are produced, and how they impact every phase of the building process—from design to inspection.

What is a Truss Certificate?

A truss certificate, sometimes referred to as a truss design certificate or truss engineering certification, is an official document issued by a licensed structural engineer or truss manufacturer. This certificate confirms that the design of the trusses meets local building codes, load-bearing requirements, and other engineering standards. It includes critical data such as:

- The name and license number of the engineer

- Project-specific details (site address, client name, building type)

- Truss design loadings (dead load, live load, wind load, snow load)

- Lumber and plate specifications

- Truss spacing and orientation

- Engineering software used for design

- Applicable design codes (e.g., ASCE 7, IBC, or local codes)

The certificate essentially serves as a stamp of approval, validating that the trusses are safe, suitable, and legally compliant.

Why Truss Documentation is Essential

1. Code Compliance

One of the primary reasons truss documentation is indispensable is that it helps ensure compliance with building codes and regulations. Trusses must be designed in accordance with state, national, or municipal codes depending on the project’s location. These codes vary by region, particularly in areas prone to specific risks like high winds, earthquakes, or heavy snow. Without verified documentation, building officials cannot confirm whether the trusses meet the structural requirements.

2. Engineering Accountability

Truss certificates legally bind the design to a licensed engineer’s professional responsibility. This means that if a truss were to fail due to design error, the engineer who signed off on the truss certificate could be held liable. This creates a system of checks and balances that encourages careful, accurate design and manufacturing.

3. Inspection and Approval

Before a building can receive final approval for occupancy, local building inspectors will review the truss documentation as part of the structural inspection. Truss certificates provide the necessary data to verify that the installed trusses match the design specifications. Any discrepancy between the actual installation and the certified design could lead to delays, fines, or even forced reconstruction.

4. Construction Accuracy

Truss documentation also serves as a guide for builders and contractors. Layout diagrams, connection details, and bracing requirements found in truss plans help ensure the trusses are installed correctly and safely. Improper installation—even of correctly designed trusses—can lead to sagging, shifting, or even collapse. Having detailed documentation mitigates this risk.

Types of Truss Documentation

In addition to the primary truss certificate, several other documents may be issued as part of the truss design and manufacturing process:

- Truss Layout Plans: These show the position of each truss in the building’s roof structure, often labeled by a unique code or identifier.

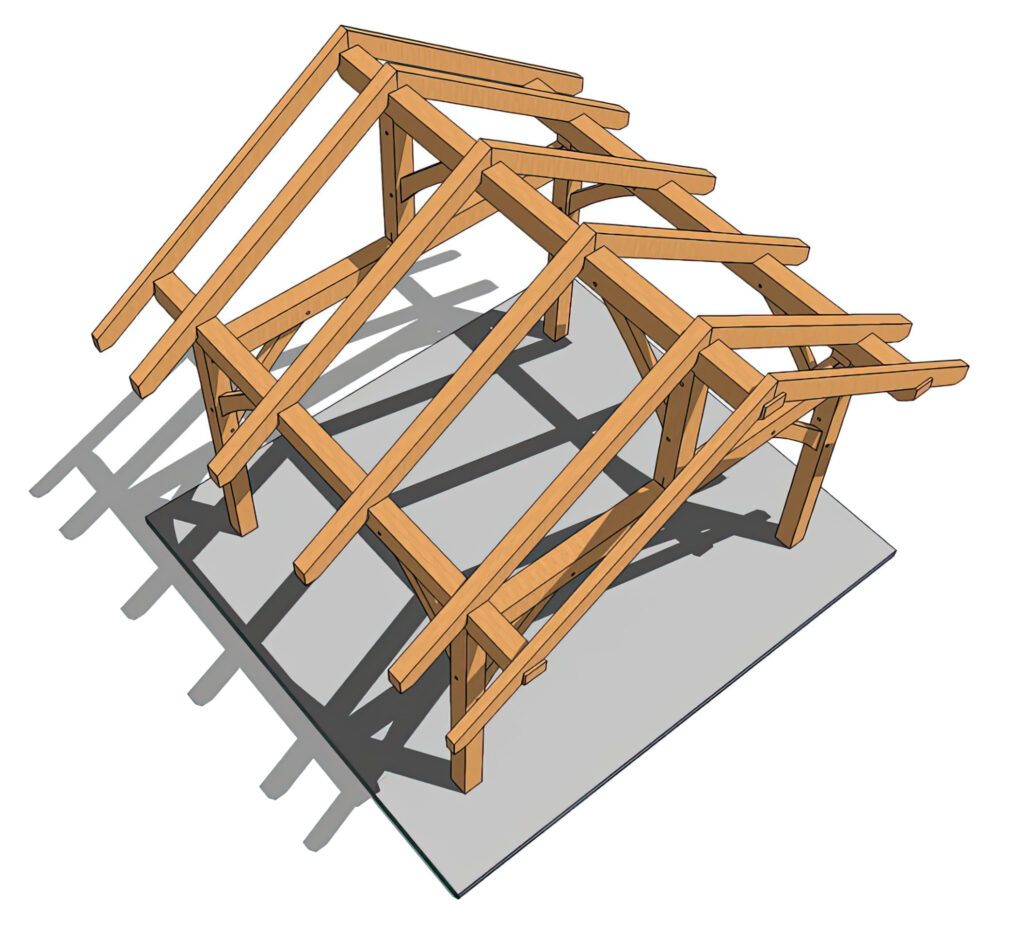

- Individual Truss Drawings: Detailed diagrams of each truss, showing angles, member sizes, plate locations, and loads.

- Bracing Instructions: Critical for installation, showing how lateral and diagonal bracing should be applied.

- Load Diagrams: Charts or schematics indicating how different loads (dead, live, wind, etc.) affect the truss.

- Calculation Reports: Often provided upon request, showing the structural calculations and engineering rationale behind each design.

All these documents form a comprehensive truss submittal package, which must be approved by the architect, engineer of record, or building official before construction begins.

The Manufacturer’s Role

Truss manufacturers play a pivotal role in both creating and maintaining accurate documentation. Using specialized design software such as MiTek or Alpine, manufacturers generate designs that are reviewed and sealed by a licensed engineer. They are responsible for ensuring that:

- Designs reflect site-specific conditions (e.g., climate, span, roof slope)

- Only appropriate materials are used

- Documentation is up-to-date and consistent across all trusses

- All drawings and certificates are available to the builder and inspector

Proper documentation also aids in quality control. If a problem arises during or after construction, manufacturers and builders can refer back to the truss documentation to determine if it was a design flaw, a manufacturing defect, or an installation error.

Consequences of Missing or Inadequate Truss Documentation

Failing to provide proper truss documentation can have serious consequences:

- Inspection Failure: Missing certificates can delay inspections and prevent the project from advancing.

- Legal Liability: If a structural issue arises and no certified documentation exists, both builders and manufacturers may face legal action.

- Insurance Issues: In the case of structural failure or damage, insurance claims may be denied if documentation cannot prove that the trusses were compliant.

- Safety Risks: The worst-case scenario is structural collapse, which endangers lives and can result in significant property damage.

Digital Documentation and Modern Trends

With the rise of digital platforms and cloud storage, more truss manufacturers and builders are transitioning to electronic truss documentation. This offers several advantages:

- Easy access and sharing between project stakeholders

- Secure storage and backup

- Faster approvals and revisions

- Integration with Building Information Modeling (BIM) systems

Some jurisdictions even mandate digital submission of truss certificates for permitting purposes, especially in urban or high-volume construction areas.

The Importance of Coordination

For documentation to be effective, coordination between all parties is crucial. Truss engineers must communicate with the architect and structural engineer of record to ensure alignment of structural design. The builder must receive all documents well before framing begins. Building inspectors must be given full access to the certificate and plans for review.

Truss documentation is not a one-size-fits-all product—it must be tailored to the building. If changes occur during construction, such as a revision to the roof pitch or wall height, the truss documentation must be updated and re-certified accordingly.

Conclusion

Truss certificates and documentation are the backbone of structural integrity in roof construction. They provide assurance that trusses are engineered to handle specific loads, follow regulatory codes, and are safe for installation. Beyond satisfying legal and inspection requirements, they serve as essential guides for builders and protect all parties involved—from engineers and contractors to homeowners and insurers.