In the world of construction, especially in roofing and structural framing, trusses play a vital role in supporting buildings efficiently and economically. Unlike traditional framing systems, trusses are pre-engineered components that distribute loads across broader spans with precision and reduced material use. However, this efficiency does not come automatically. Trusses require detailed engineering and meticulous manufacturing. Each truss must be carefully designed not just to support the building structurally but also to meet the specific requirements of local building codes, climate conditions, and load considerations.

What Are Trusses?

Trusses are pre-fabricated structural frameworks composed of triangular units that work together to distribute weight and resist external forces. Commonly made from wood or steel, trusses are widely used in residential, commercial, and industrial construction due to their cost-effectiveness, speed of installation, and structural reliability. Whether for supporting roofs or floors, trusses offer a solution that is both lightweight and strong.

The triangular geometry of trusses makes them extremely efficient in bearing loads. Each angle and connection point within a truss is calculated to handle specific forces such as compression, tension, and shear. This geometry, however, demands a level of precision that traditional stick-framing does not. It is here that engineering plays a crucial role.

The Engineering Behind Trusses

The process of designing trusses begins long before the first piece of wood or metal is cut. Truss engineers use advanced software and strict engineering principles to analyze and calculate the exact specifications each truss must meet. These calculations are based on a variety of factors including:

- Span length

- Type of building

- Roof pitch and design

- Dead loads (weight of the truss and roofing materials)

- Live loads (temporary loads such as snow, wind, and people)

- Point loads from HVAC units or other equipment

- Seismic and wind zone ratings

Engineering software generates a detailed plan for each truss, including joint locations, connector types, material grades, and load paths. These details ensure that the trusses will safely carry all anticipated forces throughout the life of the building.

Each truss design must be approved by a licensed structural engineer who certifies that the design complies with applicable codes and standards. This certification is often a legal requirement, especially for commercial or multi-family structures.

Adapting to Local Building Codes

One of the most important aspects of truss engineering is compliance with local building codes. Building codes vary significantly by region and are influenced by climate, geography, and historical data. For example, areas prone to heavy snowfall require trusses designed to handle greater live loads, while regions with frequent high winds or hurricanes need reinforced connections and bracing systems.

In the United States, most local codes are based on the International Building Code (IBC) and International Residential Code (IRC), but often with regional amendments. Engineers must be familiar with the specific code requirements for the project’s location to ensure the trusses are legally and structurally compliant.

For instance:

- In Florida, wind uplift resistance is a major factor due to hurricane risk.

- In Colorado, snow load considerations can be extreme in mountainous areas.

- In California, seismic loads are factored heavily into truss design.

A failure to comply with local codes can result in denied permits, costly redesigns, construction delays, or even structural failure in extreme cases.

Manufacturing Trusses: Precision and Quality Control

Once the engineering is complete, the trusses move into the manufacturing phase. This step is just as critical as the design process. Truss manufacturers operate with tight tolerances, ensuring that each component is cut, joined, and assembled exactly as specified in the engineering plans.

Key steps in manufacturing include:

- Material Selection: Trusses are typically made from high-quality kiln-dried lumber or steel. For wood trusses, each piece is selected based on grade and strength.

- Cutting and Fabrication: Using automated saws and CNC machinery, each component is cut to precise lengths and angles.

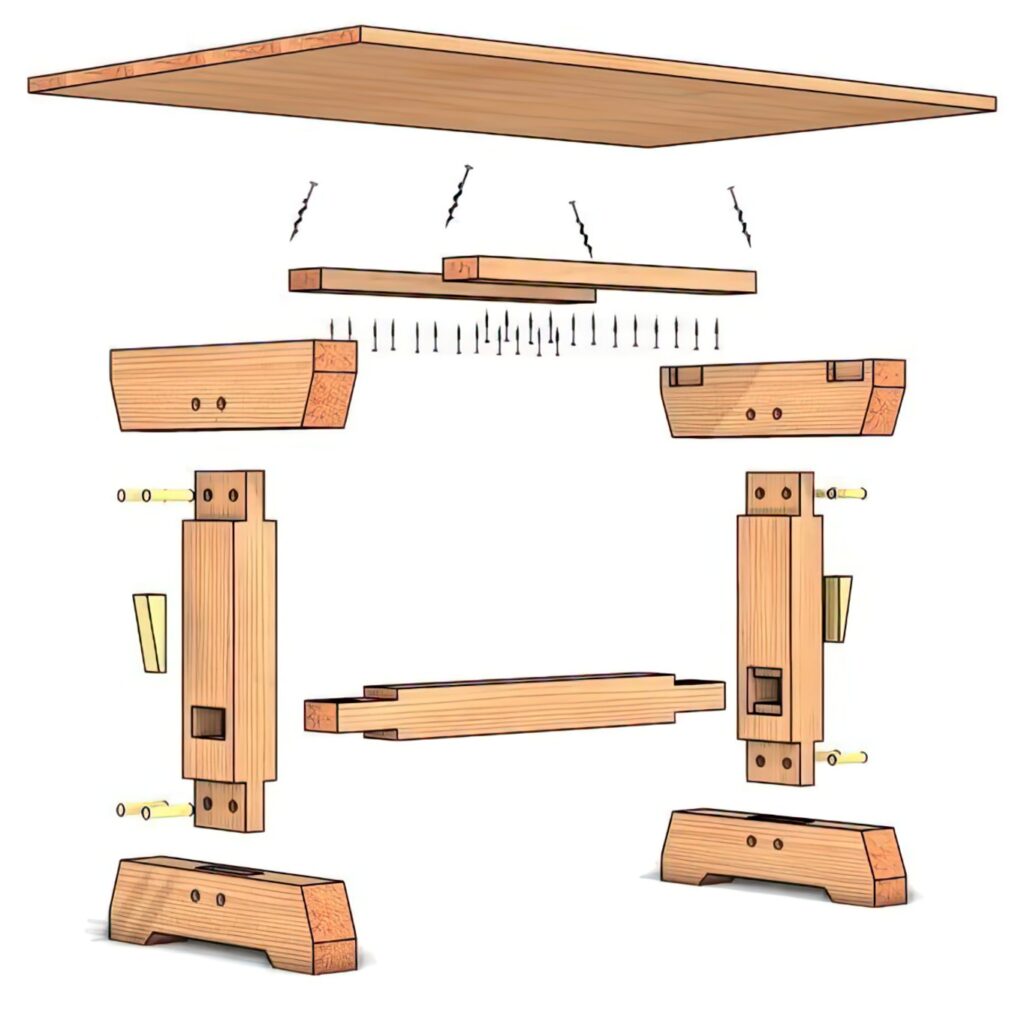

- Assembly: Components are assembled on large jigs to ensure dimensional accuracy. Gang nail plates or steel connectors are pressed into the joints using hydraulic presses or rollers.

- Inspection and Quality Control: Every truss is inspected for alignment, plate placement, and structural integrity before it leaves the factory.

Manufacturing errors can compromise the strength and function of a truss. Therefore, consistent quality control and strict adherence to engineering specifications are mandatory.

The Role of Truss Certificates and Documentation

To further ensure safety and compliance, each truss typically comes with a truss certificate or engineering seal, a document that provides:

- The truss design details

- Load specifications

- Compliance with local codes

- The engineer’s signature and license number

These documents are often required by local permitting offices before construction can begin. Additionally, during on-site inspections, building officials will verify that the trusses match the approved plans.

Installation: The Final Stage of the Process

Even the most precisely engineered and manufactured trusses can fail if not installed correctly. Proper installation ensures the load paths work as intended and that the structure remains stable and safe. Builders must follow the truss layout plan carefully, including correct spacing, bracing, and anchoring.

Many building codes require temporary and permanent bracing systems to be installed during and after construction. Failure to include these components can result in truss collapse, especially during high winds or seismic activity.

It’s also essential to ensure that no unauthorized modifications are made to trusses on-site. Cutting, notching, or drilling into a truss can invalidate its structural integrity and violate code compliance. Any modifications must be reviewed and approved by the original truss engineer.

Why This Process Matters

Detailed engineering and manufacturing aren’t just about compliance—they’re about safety, performance, and durability. Trusses that are improperly designed or manufactured can result in structural failure, injury, or worse. Moreover, buildings are long-term investments, and their structural systems must last for decades under a variety of conditions.

From an economic perspective, engineered trusses also reduce waste, labor costs, and construction time. Prefabricated trusses are delivered ready to install, allowing framing crews to complete roof structures in a fraction of the time compared to stick-framing.

Conclusion

Trusses are a cornerstone of modern construction, offering unparalleled efficiency and strength. However, behind every truss is a complex process of engineering and manufacturing that ensures it performs as intended. From accounting for local building codes to precision fabrication, each step plays a vital role in the success of a building project. Builders, engineers, inspectors, and manufacturers must work together to ensure that every truss meets the high standards required for safety and compliance. In the end, the effort that goes into engineering and producing trusses pays off in reliable structures that stand the test of time.