In the ever-evolving construction industry, engineered trusses have become the cornerstone of roofing and structural framing due to their unmatched strength, precision, and efficiency. As builders seek reliable, cost-effective solutions for both residential and commercial projects, engineered trusses offer a combination of structural integrity and design flexibility that traditional framing methods struggle to match. From suburban homes to expansive warehouses, trusses now dominate roof systems across the world—and for good reason.

The Evolution of Roof Framing

Historically, roofs were framed using hand-cut rafters and ridge boards, a method known as stick framing. While effective for small, simple structures, this traditional approach required extensive on-site labor and time. Additionally, it left room for inconsistencies due to human error and variations in materials. As construction methods modernized and buildings grew in complexity, a more reliable and uniform framing system became necessary.

This shift led to the rise of engineered trusses—prefabricated structural units designed using specialized software and constructed in controlled factory environments. Today, these trusses are shipped to construction sites ready to be installed with minimal adjustment, saving time, reducing waste, and increasing structural performance.

Why Engineered Trusses Are the Industry Standard

Engineered trusses have become the preferred choice for roofing and structural framing for several key reasons, most notably their strength, efficiency, and cost-effectiveness.

1. Superior Strength Through Engineering

Engineered trusses are designed using precise calculations and software that take into account various load conditions—dead loads (the weight of the roof structure itself), live loads (such as snow or maintenance workers), and wind or seismic forces. These calculations ensure that each truss is built to handle the specific demands of its installation location.

The strength of trusses also comes from their triangular design, one of the most stable structural forms in engineering. By distributing loads across multiple points and members, trusses prevent sagging and deformation. They also provide resistance against forces such as uplift from high winds, which is essential in hurricane-prone or storm-heavy regions.

2. Efficient Use of Materials

Engineered trusses use smaller and more consistent lumber sections than traditional rafters. This optimization not only reduces waste but also allows builders to meet structural needs without relying on large, expensive timbers. The use of metal connector plates at joints helps hold the assembly together securely, creating a strong, lightweight framework.

In factory settings, manufacturers maximize material use and reduce offcuts through computer-guided saws and jig systems. These efficiencies ultimately reduce material costs and contribute to more sustainable building practices.

3. Faster Construction

Prefabricated trusses arrive at the job site ready for installation, which significantly reduces on-site labor. In contrast to stick framing, which requires carpenters to cut and assemble each component individually, trusses can be craned into place and fastened quickly.

This faster installation speeds up the construction timeline and reduces exposure to weather-related delays. It also lowers the overall labor cost and minimizes the risk of injuries from prolonged or repetitive tasks.

Applications in Residential and Commercial Construction

Engineered trusses are used in both residential and commercial projects, but their advantages are particularly evident in large or complex structures.

Residential Use

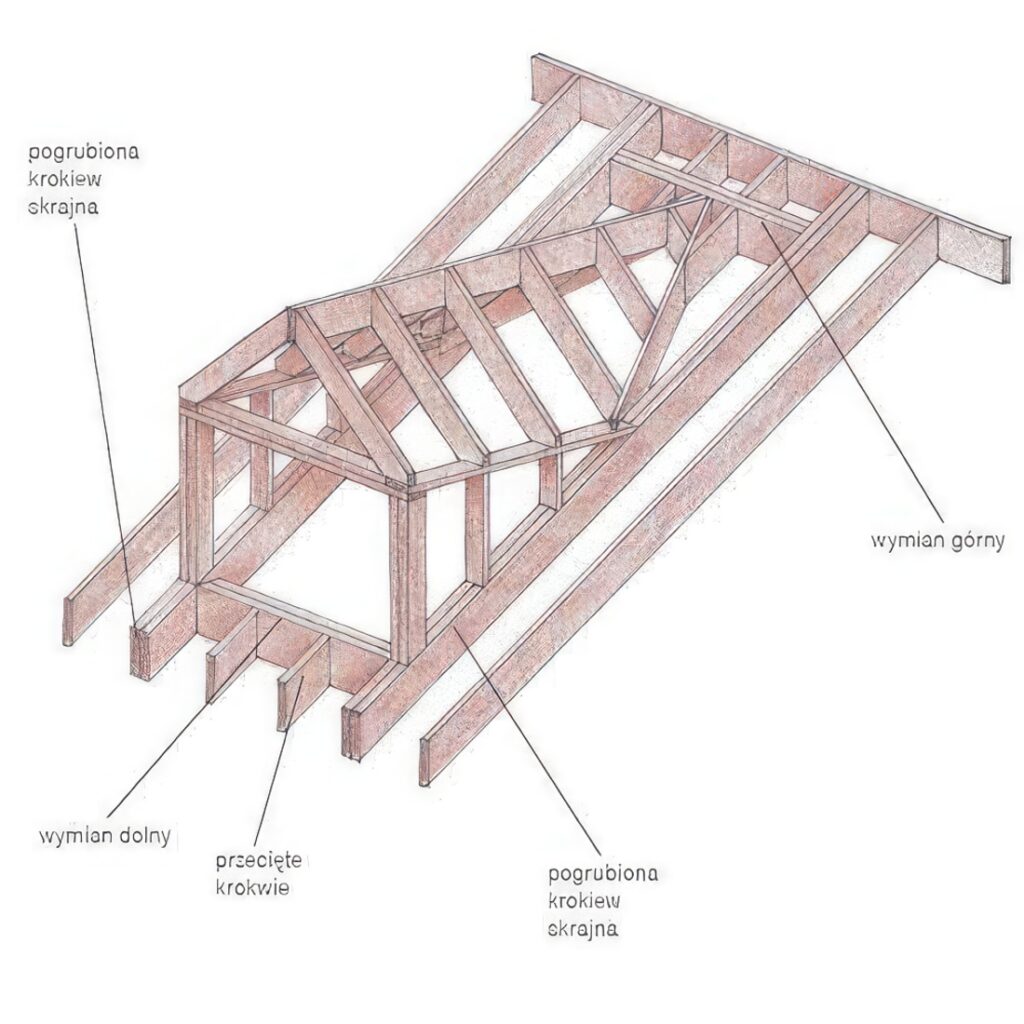

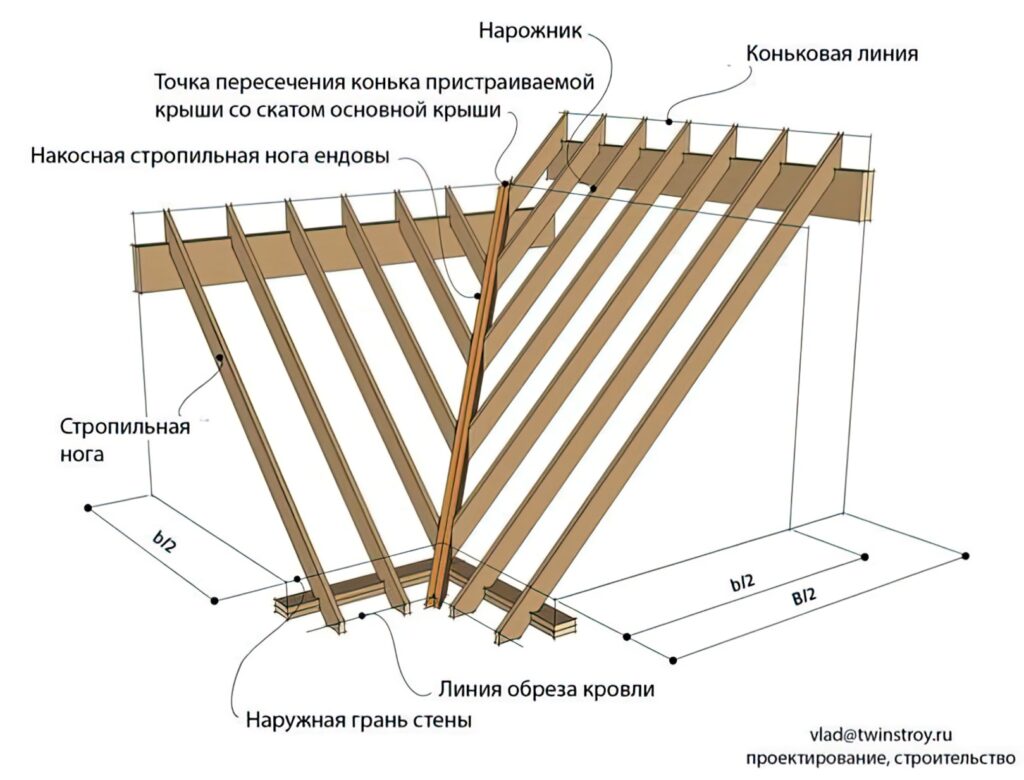

In homes, trusses are commonly used to form pitched roofs with gables, hips, or other architectural features. Builders can choose from a wide variety of truss types—such as king post, queen post, fink, howe, and scissor trusses—depending on the desired shape, attic space, and ceiling style.

Engineered trusses also allow for longer spans without interior load-bearing walls. This opens up design possibilities, enabling open floor plans and vaulted ceilings, which are highly sought after in modern residential design.

Commercial Use

In commercial settings—like warehouses, schools, or shopping centers—engineered trusses offer even greater advantages. Large buildings often require long-span trusses that can stretch over 60 feet without support columns. These allow for open, unobstructed interior spaces that are ideal for functional layouts.

Heavy-duty trusses can also be designed to support mechanical systems, suspended ceilings, and roofing materials like metal sheeting or tile. Their high load capacity and reliability make them ideal for commercial roofs subjected to greater stress and environmental exposure.

Customization and Flexibility in Design

Every building has unique structural and aesthetic requirements. Engineered trusses offer a high degree of customization. Using advanced software, truss designers can modify angles, depths, web configurations, and pitches to meet the exact needs of an architect’s vision or a structural engineer’s calculations.

This flexibility allows trusses to integrate seamlessly with HVAC ducts, skylights, chimneys, and even solar panels. Trusses can be designed to include chase openings or varying depths for different parts of the roof. Whether a project calls for cathedral ceilings or hidden attic storage, engineered trusses can accommodate it.

Quality Control and Reliability

Because trusses are manufactured in controlled environments, they benefit from rigorous quality control processes. Factory conditions reduce exposure to weather, moisture, or insects that can compromise lumber quality on site. Machines used in truss production ensure accurate cuts, consistent assembly, and reliable joint connections.

Each truss is typically reviewed and approved by a licensed engineer. This oversight adds a level of accountability and confidence that field-built framing often lacks. Builders and homeowners alike benefit from this peace of mind.

Truss Documentation and Certification

With every engineered truss system comes a set of documentation, including layout drawings, load calculations, and stamped engineering certificates. These documents are crucial during the inspection process and serve as proof that the trusses meet all applicable building codes and design criteria.

Inspectors, contractors, and code officials rely on these documents to ensure the roof system is safe and compliant. They also help guide proper installation and highlight any special bracing or support requirements.

Cost Benefits

Although the upfront cost of engineered trusses might seem comparable to traditional framing, the total project savings are substantial. Reduced labor time, minimized material waste, and decreased risk of error all contribute to lower overall costs. Additionally, faster roof installation helps speed up the building timeline, reducing overhead costs for the project owner.

Safety Advantages

From a safety standpoint, engineered trusses eliminate many of the hazards associated with complex on-site framing. With prefabricated systems, fewer workers are required to spend time at dangerous heights, and crane placement minimizes manual handling of heavy components.

Moreover, consistent manufacturing and engineering reduce the chance of structural failure due to miscuts, misalignments, or poorly secured joints.

Conclusion

In today’s construction landscape, engineered trusses have become the gold standard in roofing and structural framing. Their strength, precision, and efficiency surpass traditional methods, offering benefits in design, cost, labor, and safety. Whether building a modest home or a massive commercial complex, contractors and designers alike turn to engineered trusses as a reliable, adaptable solution.

As building codes become more stringent and the demand for performance-driven construction grows, engineered trusses are poised to remain at the forefront of structural framing. Their ability to merge strength with innovation makes them not only a current industry standard but a cornerstone of construction’s future.