In the rapidly evolving world of architecture and construction, trusses have emerged as one of the most versatile and essential structural components. Traditionally used to provide support for roofs and large spans, trusses are now stepping into a new era of relevance, shaping the way architects and engineers design commercial spaces. From warehouses and shopping centers to airports and sports arenas, trusses are no longer just a behind-the-scenes support system—they are increasingly integral to the visual and functional identity of modern buildings.

What Makes Trusses So Important in Commercial Construction?

A truss is a structural framework, typically made from wood, steel, or engineered materials, designed to distribute loads efficiently across a span. By using triangular geometry, trusses achieve incredible strength with minimal material. This allows them to cover wide areas without the need for intermediate supports, a quality that makes them ideal for commercial buildings that demand open, unobstructed interior spaces.

In retail environments, for example, trusses eliminate the need for intrusive columns, creating open layouts that enhance the shopping experience. In warehouses or factories, trusses support high ceilings and clear spans, enabling the installation of heavy equipment, overhead cranes, and efficient storage systems. Their adaptability, efficiency, and strength have made trusses indispensable in nearly every commercial sector.

But their role is expanding beyond mere functionality. Today, trusses are being reimagined as design statements, sustainability enablers, and even smart building components.

From Hidden Frameworks to Architectural Features

Historically, trusses were hidden away—covered by ceilings, drywall, or roofing materials. But modern design trends are increasingly celebrating the truss as an exposed architectural element.

Think of iconic spaces like airport terminals, stadiums, or large atriums in corporate headquarters. In many of these buildings, the truss is front and center, providing both structural support and visual impact. Exposed steel trusses can create an industrial, modern aesthetic, while timber trusses offer warmth and a natural appeal.

Architects now see trusses as design opportunities:

- Custom shapes and configurations can turn a truss system into a sculptural centerpiece.

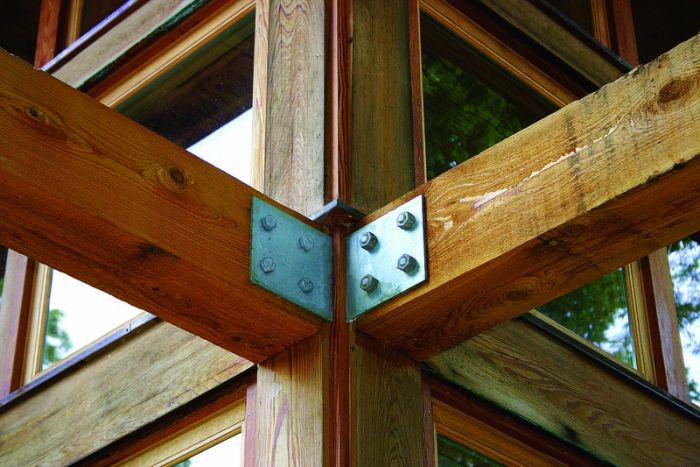

- Mixed-material trusses (like wood and steel hybrids) blend strength and beauty.

- Painted or coated trusses in bold colors can complement branding or create striking interior themes.

By merging form and function, trusses are helping to redefine the look and feel of commercial spaces.

Material Evolution: Beyond Wood and Steel

Trusses have long been built from timber (primarily in residential and light commercial applications) and steel (for larger, heavy-duty projects). But in modern commercial design, new materials are expanding possibilities.

- Mass Timber and Engineered Wood: As sustainability becomes a major goal, mass timber is gaining traction in commercial projects. Trusses made from cross-laminated timber (CLT) or glue-laminated timber (glulam) are strong, sustainable, and visually appealing. They store carbon instead of emitting it, making them attractive for environmentally conscious developers.

- Advanced Steel Alloys: Steel remains a dominant material for commercial trusses, but improved alloys and manufacturing techniques are producing lighter, stronger, and more corrosion-resistant options, reducing maintenance and extending service life.

- Composite and Hybrid Trusses: Designers are beginning to experiment with hybrid systems—for example, combining steel chords with carbon-fiber components to achieve superior strength-to-weight ratios. While these technologies are currently costly, they hint at the future direction of truss innovation.

This diversification in materials isn’t just about aesthetics or performance—it’s also about meeting new codes, green building standards, and structural demands in increasingly ambitious projects.

The Prefabrication Revolution

Another major factor driving the rising role of trusses in commercial design is prefabrication.

Prefabricated trusses are built off-site in controlled factory settings, then shipped to the construction site for assembly. This approach brings several key benefits:

- Faster construction timelines—critical in commercial projects where delays mean lost revenue.

- Improved precision and quality control, since factory fabrication reduces human error.

- Lower labor requirements on site, which is vital given the construction industry’s ongoing skilled labor shortage.

The future is trending toward modular truss systems that can be assembled like building blocks. This modularity allows for easier customization, scalability, and even future adaptation. For instance, a commercial warehouse might be designed with modular trusses that could later be swapped or reconfigured to accommodate a change in use—like converting a storage facility into a retail complex.

Smart Trusses: Technology Meets Structure

As the construction industry embraces digital technology, trusses are evolving from static elements to smart systems.

Imagine a truss embedded with sensors that monitor stress, temperature, or vibration in real time. Such trusses could:

- Alert maintenance teams to potential structural issues before they become major problems.

- Provide data for long-term performance tracking, helping engineers design even more efficient systems.

- Integrate with building management systems, feeding information to owners and operators about the structure’s health and performance.

Trusses may also play a role in energy efficiency and sustainability technologies. Future designs could incorporate solar panels directly into truss systems, support green roofs, or house conduits for smart lighting, HVAC, and electrical systems—all seamlessly built into the structural framework.

The Sustainability Imperative

Sustainability is no longer optional—it’s a driving force in every aspect of modern commercial design. Trusses, with their material efficiency and adaptability, are inherently sustainable compared to other framing methods.

Here’s how their role will grow in green construction:

- Material Optimization: Trusses use less material to achieve the same span strength as solid beams, reducing resource consumption.

- Low-Carbon Materials: Mass timber trusses, recycled steel, and even experimental bio-based composites will make future trusses key players in reducing the carbon footprint of commercial buildings.

- Support for Renewable Features: Trusses can carry the weight of solar panels, wind microturbines, and living roofs, helping buildings meet net-zero energy goals.

The combination of efficiency, adaptability, and green potential means trusses will be at the heart of sustainable commercial architecture.

Challenges on the Horizon

While the outlook for trusses is exciting, there are hurdles to overcome:

- Cost Considerations: Cutting-edge materials like carbon fiber or complex hybrid trusses are still expensive, limiting their widespread use.

- Evolving Building Codes: As trusses adopt new materials and technologies, codes and regulations must keep pace to ensure safety and compliance.

- Skilled Workforce Needs: Prefabricated and modular trusses require specialized skills for transport, assembly, and installation. Training the workforce will be crucial to fully realize their potential.

These challenges are not roadblocks—they are opportunities for innovation and collaboration between engineers, architects, regulators, and manufacturers.

Conclusion: A Framework for the Future

Trusses have always been about strength, efficiency, and practicality. But in modern commercial design, they are becoming something much more: aesthetic features, sustainability solutions, and smart infrastructure.

The rising role of trusses is evident in every corner of the industry. Airports use them to achieve vast, airy concourses. Retail chains rely on them for cost-effective, open-floor layouts. Cutting-edge architects showcase them as visual centerpieces. And forward-thinking engineers are experimenting with new materials and technologies to make trusses lighter, stronger, and smarter than ever before.

As commercial construction evolves, one thing is clear: trusses will continue to rise—both literally and figuratively—shaping not just the roofs they hold up, but the very future of design itself.